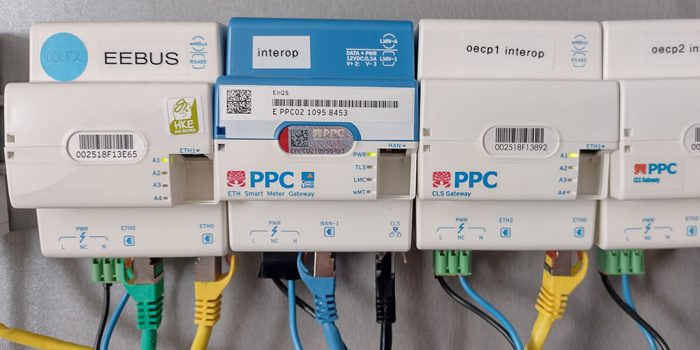

We have installed numerous measuring points and sensors in our laboratories and offices in order to display our energy consumption precisely and transparently. In addition to various smart plugs, we also use 3-phase electricity meters of the type EM300 as well as DC meters to record the electrical power at the DC strings of the PV system and at the battery storage units.

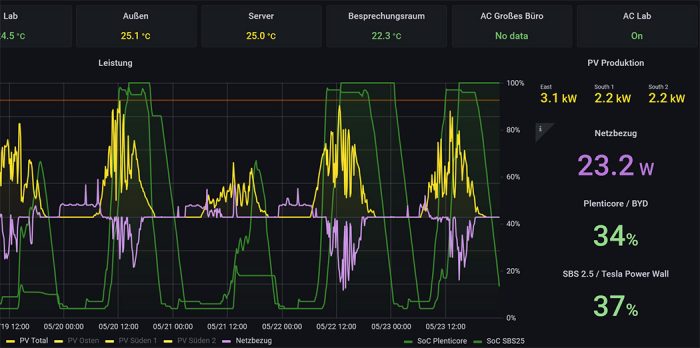

We operate a self-developed energy management system (EMS) to visualize the measurement points for the EnQS team and to control the air conditioning and heating. In addition to visualizing the local energy flows, the system is also used to test new optimization procedures or the connection of additional devices quickly and with real data. Furthermore, the EMS is used to support device and software tests in the EnQS Testlab.

We control our air conditioning systems with the EMS so that A/C is only supplied with surplus power from the PV system. Due to the fluctuation of PV generation and home consumption, as well as possible damage caused by constantly switching the system on and off, air conditioning engineers do often not support approaches to dynamically control such systems. Using forecasts of consumption and generation, consideration of technical system constraints (e.g., minimum run times), and state of the art computer science methods, we implemented predictive control to drive the air conditioners. Since our EMS has been in operation, we have been cooling exclusively with surplus electricity from our PV system. Due to the strong temporal correlation between solar irradiation and cooling demand, the coordination of PV system and air conditioning is particularly useful and economical.

We continue to buffer surplus energy from the photovoltaic system in various battery storages. When prioritizing the systems, the EMS takes into account, for example, the maximum charging and discharging capacities as well as the available capacity of the storage systems. The actual control of the storages is implemented with a PID controller, which we continuously adjust based on the knowledge gained through continuous operation.

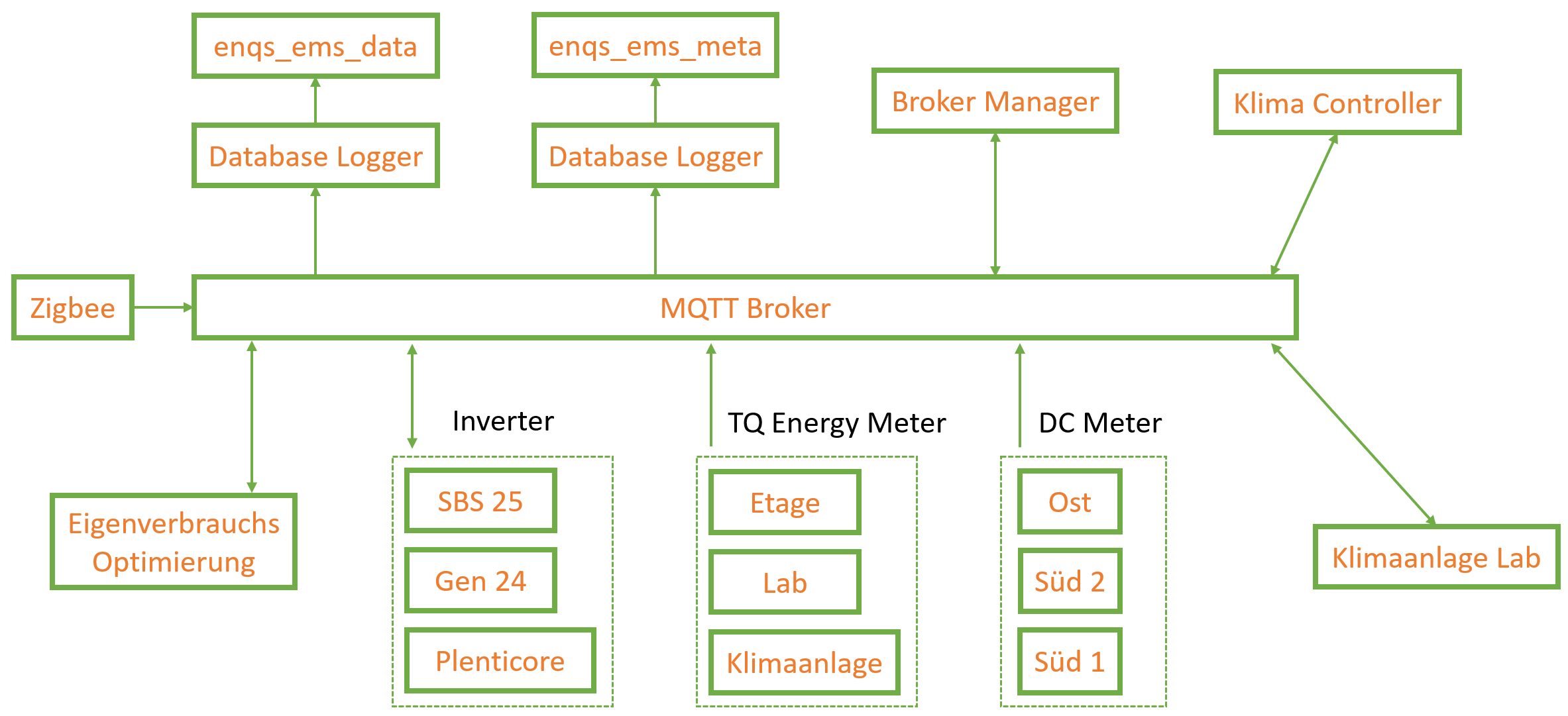

Technically, the EMS is composed of numerous Micro Services that communicate bidirectionally via an MQTT broker with asynchronous multithreading and are implemented within individual Docker containers. The modular driver structure allows new devices to be integrated into the EMS quickly and during runtime. Since the system is used exclusively in our own premises, it runs with a purely local backend.

We integrated the different protocols of the concrete devices and systems (ModbusTCP, ModbusRTU, REST, etc.) via corresponding adapters, which are also realized as Micro Services. Logging is done every second into a time series database (InfluxDB) and visualization is expediently done via Grafana.

A Broker Manager provides an overview of all running Micro Services and also provides information about the device on which they are currently active. The structure basically allows the Micro Services to run on distributed hardware systems. This makes the system very scalable.

Additional services such as watchdog, alerting and a Slack bot make it easier for us to operate the installed systems in our daily work.

With the long-term collected database as well as the monitoring of the concrete devices in continuous operation, we develop additional know-how that we are happy to share with our customers and partners.

< back to overview