EnQS Testlab

The EnQS Testlab is at the heart of the EnQS service portfolio. Here we test your energy management and IoT solution, evaluate prototypes, develop software for energy management and IoT solutions and use the comprehensive infrastructure for analyses as well as technical consulting.

We combine electrical engineering and computer science to make the setup, operation, and expansion of individual test and development systems as flexible and efficient as possible. You benefit from short communication paths and uncomplicated solutions.

During software development for energy management and IoT systems, direct access to the actual devices is often required in order to be able to detect and take into account errors, e.g. in the interface description, at an early stage. We build individual test and development environments, operate them 24/7 and provide you with remote access to the system if required.

The systems in the EnQS Testlab range from complete energy management and IoT solutions (PV/battery inverters, CHPs, battery systems, EV charging stations, heat pumps/heating units, gateways, network technology, etc.) to setups for connectivity analyses of radio-based communication. You benefit from our experience in the setup as well as in the selection of suitable measurement technology and analysis methods.

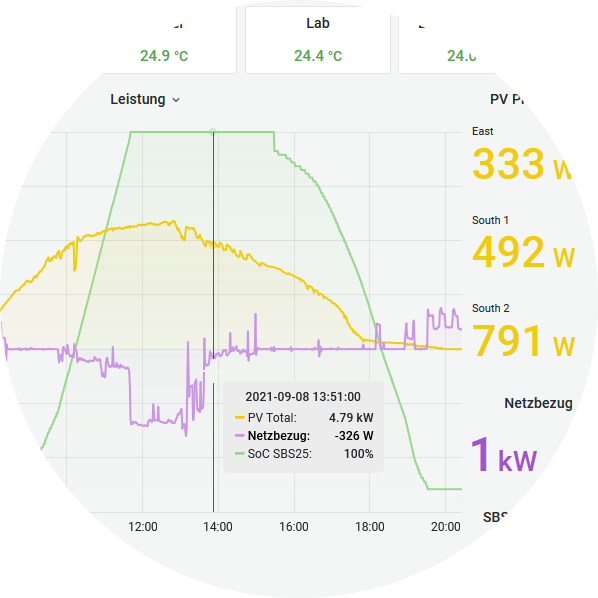

PV-System for Real Production Profiles

The three strings of our real PV plant (in south and east orientation) in combination with automated consumption circuits enable realistic operation of the energy management and IoT systems in the EnQS Testlab. Possible errors in operation with the real plants are thus already noticed during testing or development work.

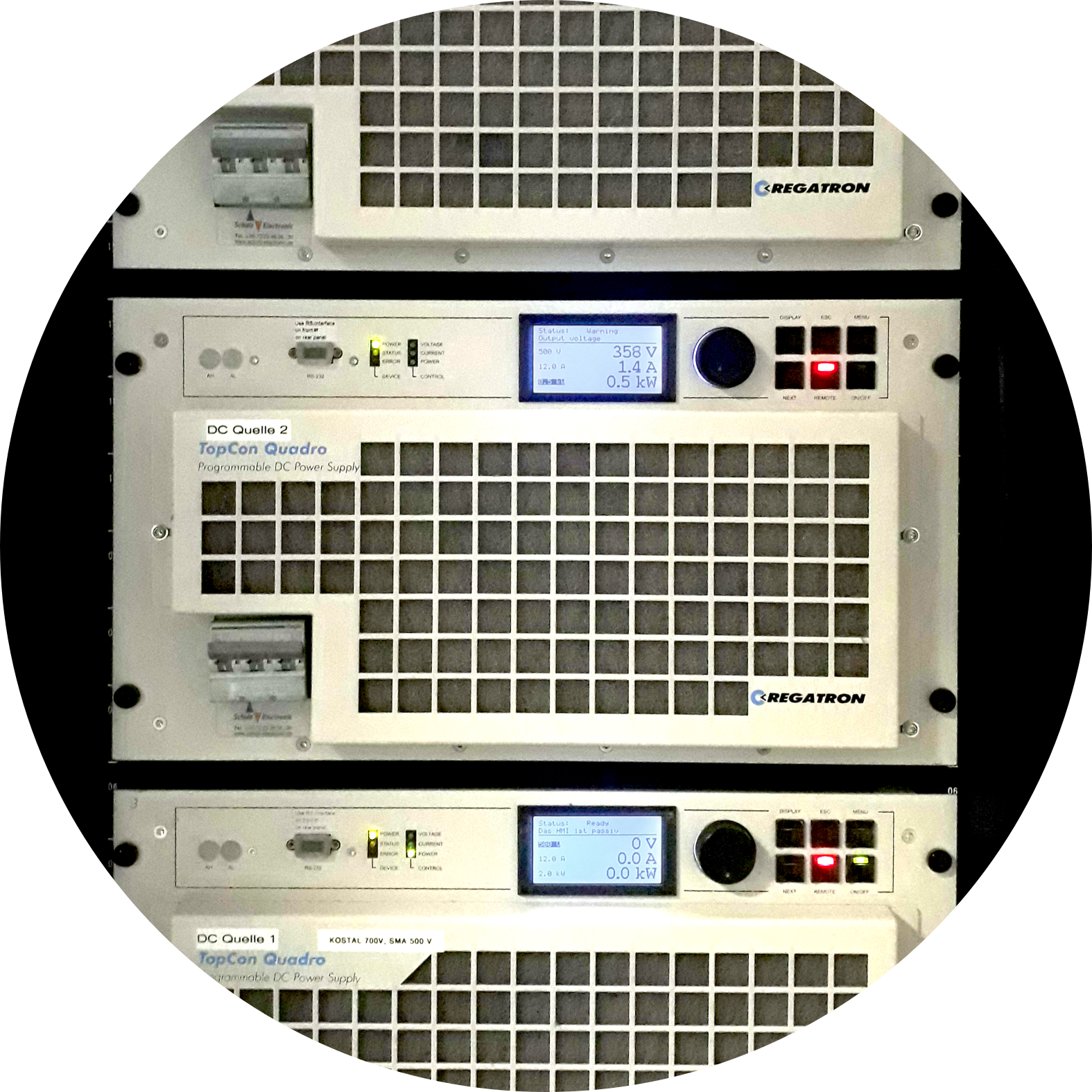

DC-Generators for Synthetic Load Profiles

To generate synthetic PV profiles, 5x TopCon Quadro DC generators (16 kW each at 0-800 V) from the Swiss manufacturer Regatron are available in the EnQS Testlab. In combination with specially developed software, we can, for example, play back PV profiles of a summer day independently of the actual PV output and thus evaluate, for example, procedures for compliance with the 60/70% rule at the grid connection point or system reactions to particularly strong fluctuations. Three of the devices are also equipped with the "Solar Array Simulator (SAS)" expansion module, so that a precisely defined U/I characteristic curve can be simulated realistically.

Measurement Technology and Grid/Load Simulator

For high-precision measurements, an LMG671 power meter (32A, 1500 V) is available to carry out DC measurements with an accuracy of up to 0.025% and AC measurements with an accuracy of up to 0.04%. This measurement technology is used in particular for efficiency measurements of storage systems and for measuring standby power.

Additionally, an IT7900P High Performance Regenerative Grid Simulator (15 kVA, 350 V, 90 A) is available, which can be used to generate load profiles with defined active and reactive power components, e.g., to simulate realistic (bidirectional) charging of electric vehicles.

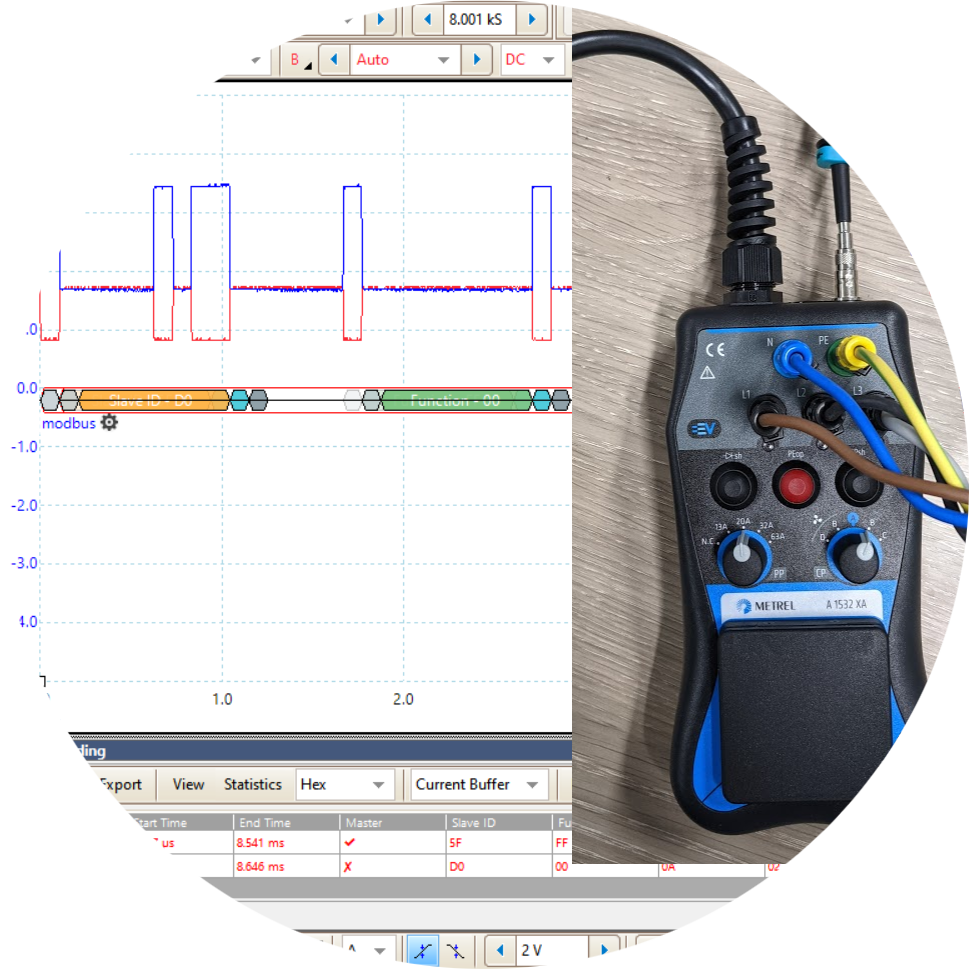

Analysis Tools and Software

Analysis tools and individually developed software enable us to efficiently analyze and/or evaluate end-to-end data streams, device interfaces and energy flows through to the distribution of radio signals (e.g. WiFi, BT LE, 868 MHz, etc.). Automated measurement data acquisition (e.g. energy flows) and tests (e.g. automated UI tests based on Selenium) enable efficient 24/7 operation of the systems in the EnQS Testlab.

Energy Management in EnQS Testlab

In the EnQS Testlab, we operate an energy management system based on state-of-the-art IoT technologies. In this way, we gain practical experience on a daily basis with regard to the development, use, operation as well as further development of energy management and IoT solutions. In the EnQS Testlab, we control in particular the heating and air conditioning system as well as the storage systems according to the PV generation.

Safety According to BGI 891

The work in the EnQS Testlab is, of course, carried out in accordance with current safety standards and, in particular, meets the requirements of BGI 891, DIN VDE 0100 and DIN VDE 0701-0702. Thus, we take the electrical responsibility for the operation of your test and development systems in the EnQS Testlab.